Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > Product Center > Gravity Concentration Equipment > Shaker equipment

Request a quotation

Request a quotation technical advice

technical advice

24-hour phone/WhatsApp:+8619870423316

24-hour phone/WhatsApp:+8619870423316

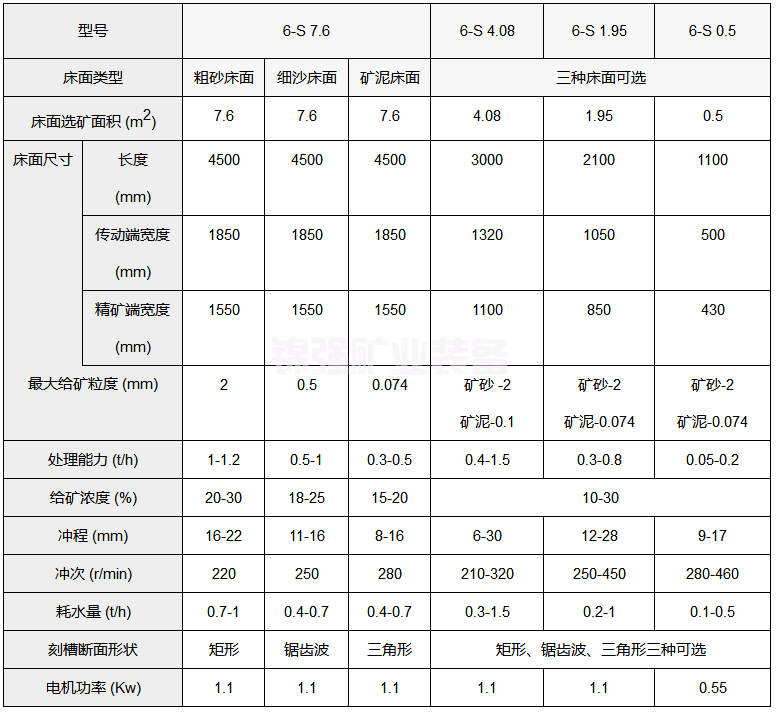

The 6S shaking table is one of the key mechanical equipment for gravity beneficiation. The 6S shaking table equipment for beneficiation is commonly used to separate non-ferrous and precious metal mines such as tungsten, tin, tantalum, niobium, iron, manganese, chromium, titanium, bismuth, lead, gold, etc. The 6S shaking table equipment for beneficiation can also be used in the coal mining industry. It can be used for different work such as coarse selection, optimization and sweeping, and can be used to separate coarse sand (2-0.5mm), fine sand (0.5-0.074mm), mineral mud (-0.074), etc. with different particle size distribution. The 6s shaking table equipment for beneficiation can also be used to separate iron, manganese ore, and coal. When solving the problem of tungsten, tin and other iron ores, the reasonable purchase particle size distribution range of 6s ore dressing shaker equipment is 2-0.022mm.  The whole process of the concentrator of the 6s ore dressing shaking table equipment is carried out on the surface of a slanted bed with multiple strips. The ore particles are fed from the ore feeding trough at the corner of the bed surface, and at the same time, the stainless steel water tank is provided with horizontal cleaning water. Therefore, under the effect of the inertial force and sliding friction caused by the force of the ore particles, the impact force of the horizontal water flow, and the reciprocating fitness exercise of the bed body, the distribution of the particles is divided into different levels according to the proportion and particle size, And perform vertical fitness exercises along the bed and horizontal fitness exercises along the tilted bed. Therefore, ore particles with different proportion and particle size distribution slowly flow down from side A to side B in fan shape along their respective fitness movement directions, and are discharged from different areas at the titanium concentrate end and the tailings pond side respectively, and are finally divided into titanium concentrate, middling and tailings pond. The glass fiber reinforced plastic anti-corrosion equipment of the

The whole process of the concentrator of the 6s ore dressing shaking table equipment is carried out on the surface of a slanted bed with multiple strips. The ore particles are fed from the ore feeding trough at the corner of the bed surface, and at the same time, the stainless steel water tank is provided with horizontal cleaning water. Therefore, under the effect of the inertial force and sliding friction caused by the force of the ore particles, the impact force of the horizontal water flow, and the reciprocating fitness exercise of the bed body, the distribution of the particles is divided into different levels according to the proportion and particle size, And perform vertical fitness exercises along the bed and horizontal fitness exercises along the tilted bed. Therefore, ore particles with different proportion and particle size distribution slowly flow down from side A to side B in fan shape along their respective fitness movement directions, and are discharged from different areas at the titanium concentrate end and the tailings pond side respectively, and are finally divided into titanium concentrate, middling and tailings pond. The glass fiber reinforced plastic anti-corrosion equipment of the  6s mineral processing shaker has high silver ore ratio, high sorting efficiency, and is very easy to take care of, which is conducive to adjusting the four stroke. By changing the horizontal inclination and four stroke, the bed can still maintain balanced operation. The bullet yellow is placed on the box body, with a compact structure, and the final titanium concentrate and tailings pond can be obtained successively.

6s mineral processing shaker has high silver ore ratio, high sorting efficiency, and is very easy to take care of, which is conducive to adjusting the four stroke. By changing the horizontal inclination and four stroke, the bed can still maintain balanced operation. The bullet yellow is placed on the box body, with a compact structure, and the final titanium concentrate and tailings pond can be obtained successively.

Advantages and Characteristics of 6s Mineral Processing Shaker Equipment

1. High utilization rate and high aggregation ratio;

The 26s beneficiation shaker equipment is easy to install and practical operation is simple;

3 fiberglass anti-corrosion bed bodies, seven different bed bodies to choose from;

The service life of the 4 ore dressing 6s shaking table equipment is long.

6s shaking table Related products

Gravity Concentration Equipment

Complete set of beneficiation equipment

Complete set of beneficiation equipment  Complete equipment for quartz sand benef

Complete equipment for quartz sand benef Complete equipment for graphite ore bene

Complete equipment for graphite ore bene Complete set of beneficiation equipment

Complete set of beneficiation equipment  Complete set of mining beneficiation equ

Complete set of mining beneficiation equ Complete energy-saving beneficiation equ

Complete energy-saving beneficiation equ Complete set of manganese ore beneficiat

Complete set of manganese ore beneficiat Gold selection complete equipment

Gold selection complete equipment Complete beneficiation equipment

Complete beneficiation equipment Complete set of sand gold beneficiation

Complete set of sand gold beneficiation