Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > Mineral processing production line

Request a quotation

Request a quotation technical advice

technical advice

24-hour phone/WhatsApp:+8619870423316

24-hour phone/WhatsApp:+8619870423316

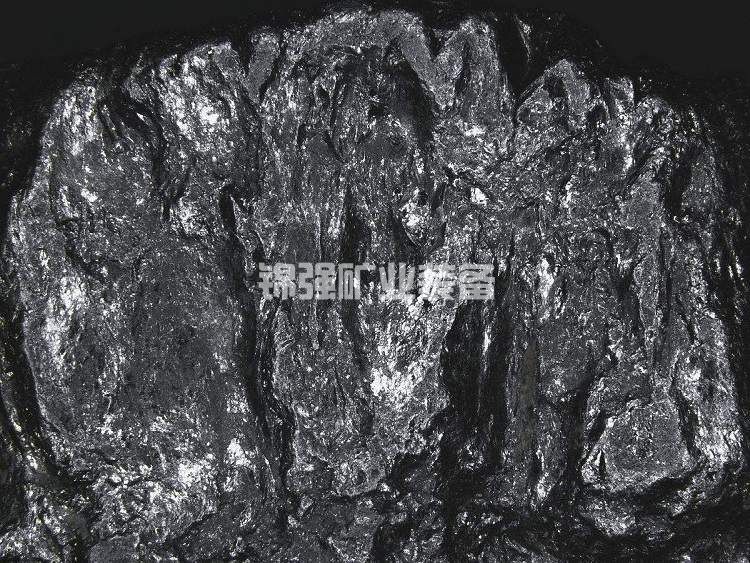

Introduction to the complete set of mining equipment and mining machinery production line: Complete set of mining beneficiation equipment - flotation equipment

The complete set of mining beneficiation equipment flotation production lines are mostly suitable for materials such as gold, molybdenum, silver, copper, nickel, limestone, fluorite, graphite, etc., with strong applicability. The complete set of mining beneficiation equipment has the characteristics of simple operation, few faults, high efficiency, low consumption, environmental protection and energy conservation.

1. Complete flotation combination of mining equipment. The complete set of mining equipment flotation production line is usually composed of a series of complete mining equipment and supporting equipment such as jaw crushers, impact crushers/cone crushers, circular vibrating screens, ball mills, spiral classifiers, mixing drums, flotation machines, thickeners, dryers, etc.

2. The flotation process flow of the entire production line of mining machinery is divided into stages such as crushing and screening, grinding and grading, flotation and drying. The specific process steps are as follows: (1) The ore material after blasting mining is preliminarily crushed by a jaw crusher, and then further crushed by impact crushing/cone crushing. It is reasonably screened into different specifications by a vibrating screen; (2) The qualified ore materials are sent to the ball mill for wet grinding processing, and then screened by a spiral classifier. The unqualified slurry is sent to the ball mill for re grinding; (3) After grading, the materials that meet the conditions will enter the mixing drum, be thoroughly mixed with water and stirred, and then enter the flotation machine to add suitable chemicals. After complete reaction, the concentrate can be obtained, which is then dehydrated by a thickener and dried by a dryer.

Complete set of mine beneficiation equipment magnetic separation equipment complete set of mine beneficiation equipment magnetic separation production line has the characteristics of high energy, high yield, energy saving, environmental protection, green, less investment, reasonable economy, and long service life. Complete set of mine beneficiation equipment is mostly suitable for the selection of magnetic minerals such as Magnetite, Pyrrhotite, Hematite, Pyrite, etc. 1. Complete set of mining equipment magnetic separation combination. The complete set of mining equipment magnetic separation production line consists of jaw crusher, impact crusher/cone crusher, circular vibrating screen, ball mill, spiral classifier, magnetic separator, thickener, dryer, and other equipment.

2. The magnetic separation process of the entire production line of mining machinery usually includes stages such as crushing, grinding, magnetic separation, etc. Each stage is interrelated and complementary. The specific process steps are as follows: (1) After the ore is mined, it is first roughly crushed using a jaw crusher, then finely crushed in the counter crushing/cone crushing process, and then sent to a vibrating screen for reasonable screening; (2) The screened ore materials that meet the grinding conditions enter the ball mill for wet grinding with water, and are then screened by a spiral classifier. The pulp materials that do not meet the conditions are then sent back to the ball mill for grinding; (3) The qualified slurry screened after classification is sent to a magnetic separator for high-energy magnetic separation treatment, then concentrated by a thickener and fully dehydrated by a dryer. In summary, the complete set of mining beneficiation equipment is not unified, and customers can provide reasonable equipment based on actual material properties, production requirements, site size, and other factors. Our company specializes in the production of mineral processing equipment, with reliable quality, multiple models, complete specifications, energy-saving, and affordable prices. Technicians plan the most complete and ideal production line for customers based on the environment, climate, materials, and economic level, provide comprehensive after-sales services, and provide free installation and transportation. Welcome to inquire and purchase!

Complete set of mining beneficiation equipment related processes

Gravity Concentration Equipment

Complete set of beneficiation equipment

Complete set of beneficiation equipment  Complete equipment for quartz sand benef

Complete equipment for quartz sand benef Complete equipment for graphite ore bene

Complete equipment for graphite ore bene Complete set of beneficiation equipment

Complete set of beneficiation equipment  Complete set of mining beneficiation equ

Complete set of mining beneficiation equ Complete energy-saving beneficiation equ

Complete energy-saving beneficiation equ Complete set of manganese ore beneficiat

Complete set of manganese ore beneficiat Gold selection complete equipment

Gold selection complete equipment Complete beneficiation equipment

Complete beneficiation equipment Complete set of sand gold beneficiation

Complete set of sand gold beneficiation