Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > Product Center > Screening equipment > Cyclone

Request a quotation

Request a quotation technical advice

technical advice

24-hour phone/WhatsApp:+8619870423316

24-hour phone/WhatsApp:+8619870423316

Hydrocyclone is used to separate and remove heavy coarse particles, sludge and other chemicals in wastewater. Sometimes it is also used to dry with mortar. It is divided into two types: working pressure type and gravity type, often made of circular cylindrical buildings or metal hoses. The water enters from the upper end of the building (or metal hose) along the broken line by working pressure or gravity. Under the effect of Centripetal force, the chemical substances of the compacted particles are thrown to the wall of the vessel and rotated downward to discharge with the generated concentrated liquid. The smaller particles of chemical substances rotate to a certain level, although they are discharged by a secondary upwelling vortex.

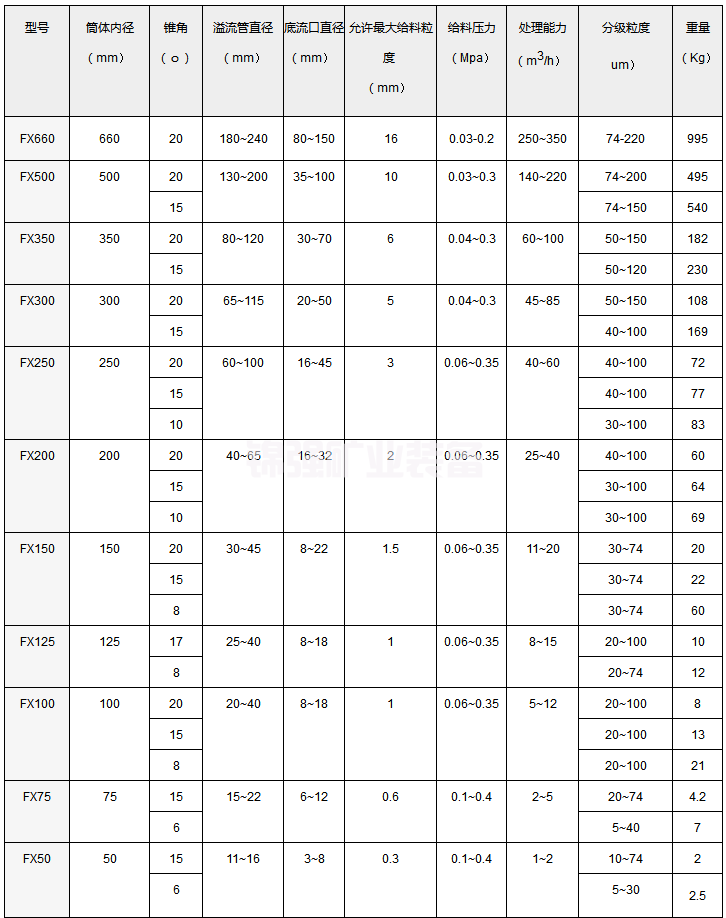

Structure of Hydrocyclone: the upper end is conical. Equipped with a feed pipe tangential to the cylinder wall on the cylindrical section. The upper end of the cone is equipped with a management center overflow pipe connected to a part of the cylinder. The upper part of the overflow pipe is connected to the buffer room or immediately connected to the external pipeline to discharge the overflow type. Equipped with a sand settling nozzle at the bottom of the cone to discharge coarse sand. In order to better reduce wear, wear-resistant rubber or metal composites such as Gabbro, cast stone and carbon carbon composites can be lined on the wall of the feed mouth, grit nozzle and cylinder body. Working principle of Hydrocyclone group: when the coal slurry enters the drum along the tangent direction through the feed pipe with a sediment pump (or slope) at a certain working pressure (generally 0.5~2.5 kg/cm) and water flow (about 5~1 2m/s), the coal slurry will rotate along the material bed at a rapid rate, resulting in a very large Centripetal force. Under the effect of Centripetal force and gravity, the coarser and heavier mineral particles are thrown to the wall of the vessel, and move down the trajectory of the vortex line to keep fit, and are discharged from the nozzle below the cone, while the finer mineral particles generate an internal spiral upward coal slurry flow in the cone management center and water, and are discharged through the overflow pipe. Compared with the mechanical equipment classifier, the Hydrocyclone group has the following advantages: no fitness components, simple structure; The production capacity of the enterprise is large, accounting for a small proportion of the total area; Hierarchical efficiency (up to 80%~90%), fine particle size distribution; The engineering cost is low and the raw material consumption is low.

Hydrocyclone group has been widely used in mineral processing technology of various metal mines. Hydraulic power is mainly used for the following work according to the process: 1. grinding and grading of the first section of cable digital TV 2. grinding and grading of the second section of cable digital TV 3. regrinding and grading of titanium concentrate 4. desliming of the raw ore before and after beneficiation 5. embankment and backfill of tailings pond

Hydrocyclone group has been widely used in mineral processing technology of various metal mines. Hydraulic power is mainly used for the following work according to the process: 1. grinding and grading of the first section of cable digital TV 2. grinding and grading of the second section of cable digital TV 3. regrinding and grading of titanium concentrate 4. desliming of the raw ore before and after beneficiation 5. embankment and backfill of tailings pond  Hydrocyclone website provides Hydrocyclone group working principle | Hydrocyclone manufacturer model information, and learn more about Hydrocyclone group working principle and manufacturer model and other product information, Welcome to inquire about Jinqiang Mining Equipment, which is sold directly by manufacturers at affordable prices. Welcome to purchase.

Hydrocyclone website provides Hydrocyclone group working principle | Hydrocyclone manufacturer model information, and learn more about Hydrocyclone group working principle and manufacturer model and other product information, Welcome to inquire about Jinqiang Mining Equipment, which is sold directly by manufacturers at affordable prices. Welcome to purchase.

Hydrocyclone Related products

Gravity Concentration Equipment

Complete set of beneficiation equipment

Complete set of beneficiation equipment  Complete equipment for quartz sand benef

Complete equipment for quartz sand benef Complete equipment for graphite ore bene

Complete equipment for graphite ore bene Complete set of beneficiation equipment

Complete set of beneficiation equipment  Complete set of mining beneficiation equ

Complete set of mining beneficiation equ Complete energy-saving beneficiation equ

Complete energy-saving beneficiation equ Complete set of manganese ore beneficiat

Complete set of manganese ore beneficiat Gold selection complete equipment

Gold selection complete equipment Complete beneficiation equipment

Complete beneficiation equipment Complete set of sand gold beneficiation

Complete set of sand gold beneficiation