Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > News and information > Reselection of knowledge

update date:2023-07-16 03:14:55Number of views: author:huang

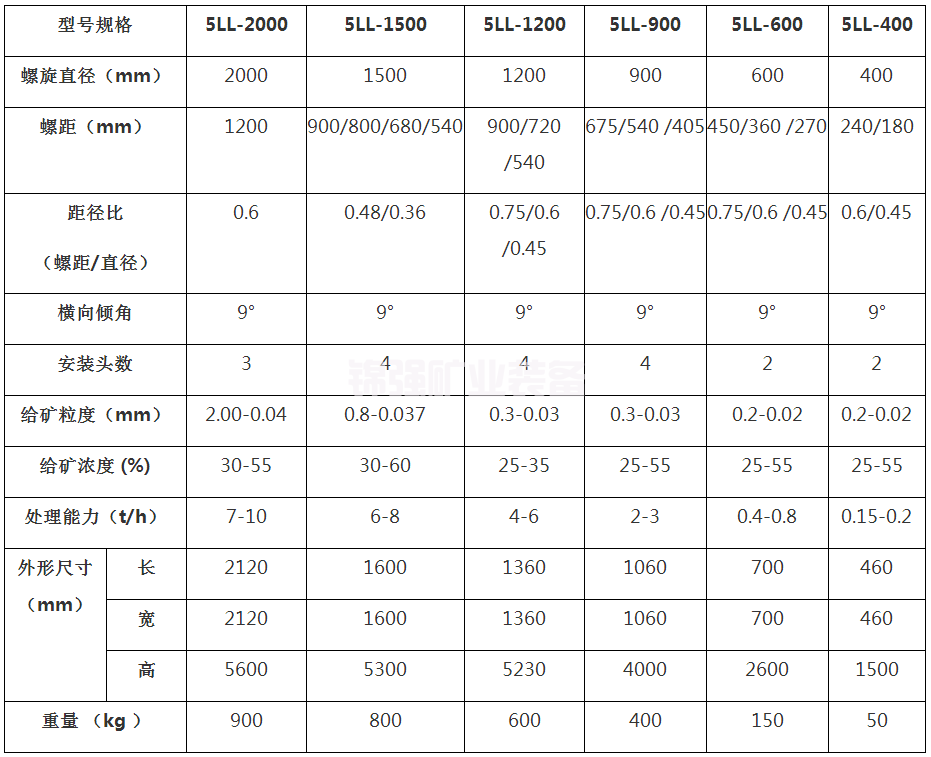

Spiral chute size and purpose 1. Product introduction: A gravity beneficiation equipment that utilizes the inertial centrifugal force that occurs during the spiral rotation movement of mineral slurry to separate light and heavy mineral materials. 2、 The glass fiber reinforced plastic spiral chute shall be set up with skills, aligned with the vertical line, and fixed in a suitable position with iron shelves or wood. The sand pump shall be used to transport the mineral sand to the two ore feeding ports above the spiral, add make-up water, and adjust the concentration of the mineral slurry. The mineral slurry naturally swirls from high to low. A single coherent centrifugal force appears in the rotating slope flow rate, and the difference in the gravity, Granularity and shape of the mineral sand is obtained, By utilizing the gravity and centrifugal force of the swirling flow, the sand and ore are separated, and the selected ore is discharged into the concentrate hopper and connected out through pipelines. The tailings enter the tailings hopper and are connected to the sand tank through pipelines, and then discharged by a mortar pump, completing the entire process of beneficiation. The size and purpose of the  spiral chute are three. Features and advantages. 1. Large scale and strong processing capacity. Today, mineral processing objectively allows for the creation of benefits through large-scale production. 2. Fine granulation: for the treatment of fine and micro particle grade minerals, especially the treatment of ore materials with a particle size of -0.047 mm, the original machine can generally ensure the recovery of+0.047 mm Granularity. 3. With the development of Hydraulics, two-phase flow, machine vibration, etc., GRP spiral chute has developed from simple use of gravity and water blocking force to composite centrifugal force, equipment vibration force, magnetic separation force, etc. Through a composite force field, the enrichment of useful minerals and the separation of fine and fine particles are increased, thereby increasing the recovery rate of ore materials. 4. With energy saving and environmental protection as the basic starting point, the area and space occupied should be small, and the water and electricity consumption should be small. 5. Convenient and flexible operation, stable sorting steps, simple structure and convenient Computerized maintenance management system. The size and purpose of the spiral chute are

spiral chute are three. Features and advantages. 1. Large scale and strong processing capacity. Today, mineral processing objectively allows for the creation of benefits through large-scale production. 2. Fine granulation: for the treatment of fine and micro particle grade minerals, especially the treatment of ore materials with a particle size of -0.047 mm, the original machine can generally ensure the recovery of+0.047 mm Granularity. 3. With the development of Hydraulics, two-phase flow, machine vibration, etc., GRP spiral chute has developed from simple use of gravity and water blocking force to composite centrifugal force, equipment vibration force, magnetic separation force, etc. Through a composite force field, the enrichment of useful minerals and the separation of fine and fine particles are increased, thereby increasing the recovery rate of ore materials. 4. With energy saving and environmental protection as the basic starting point, the area and space occupied should be small, and the water and electricity consumption should be small. 5. Convenient and flexible operation, stable sorting steps, simple structure and convenient Computerized maintenance management system. The size and purpose of the spiral chute are  . The structure of the spiral chute is composed of six parts: a feeding homogenizer, a feeding chute, a rotating chute, a product acquisition chute, an equipment gathering hopper, and a groove bracket (including a cross or triangular frame). The spiral groove formed by connecting the spiral pieces is a key component. The rotating plate is made of fiberglass (fiberglass reinforced coal gangue) and connected together by screws. The selection surface of the rotating groove has a pre made wear-resistant layer. She has the advantages of lightweight, sturdy, and durable consumer goods that are not easily damaged. The head of the spiral groove is equipped with a multi tube feeding homogenizer to sort minerals evenly, which is not cumbersome to operate. The mineral sorting device is freely placed on the cross (or tripod) of the support table. The evenly divided mortar is slowly fed onto the surface of the spiral groove through the feeding chute at the head end of the rotating groove for sorting. The tail of the rotating groove is installed in a valve block type new product selection groove, allowing the selection of new equipment to be divided into three (or four) types of new products radially according to grade. Change the cutting width of each new device by adjusting the position of the valve block. The new product gathering bucket is a concentric circular tube that distinguishes and converges the obtained multi head ore flows. The horizontal plane of the spiral concentrator is particularly suitable for the separation of small particle ore materials when the slope of the curve changes. 5、 The fiberglass spiral chute is suitable for processing 0.6-0.03MM and vein or placer ores, but it is unfavorable for sorting when the mud content is high. Now it has been widely used for processing iron ore, tungsten, tin ore, niobium tantalum ore, coastal and riverside ore sands, and gold mines. Spiral Chute Size Usage

. The structure of the spiral chute is composed of six parts: a feeding homogenizer, a feeding chute, a rotating chute, a product acquisition chute, an equipment gathering hopper, and a groove bracket (including a cross or triangular frame). The spiral groove formed by connecting the spiral pieces is a key component. The rotating plate is made of fiberglass (fiberglass reinforced coal gangue) and connected together by screws. The selection surface of the rotating groove has a pre made wear-resistant layer. She has the advantages of lightweight, sturdy, and durable consumer goods that are not easily damaged. The head of the spiral groove is equipped with a multi tube feeding homogenizer to sort minerals evenly, which is not cumbersome to operate. The mineral sorting device is freely placed on the cross (or tripod) of the support table. The evenly divided mortar is slowly fed onto the surface of the spiral groove through the feeding chute at the head end of the rotating groove for sorting. The tail of the rotating groove is installed in a valve block type new product selection groove, allowing the selection of new equipment to be divided into three (or four) types of new products radially according to grade. Change the cutting width of each new device by adjusting the position of the valve block. The new product gathering bucket is a concentric circular tube that distinguishes and converges the obtained multi head ore flows. The horizontal plane of the spiral concentrator is particularly suitable for the separation of small particle ore materials when the slope of the curve changes. 5、 The fiberglass spiral chute is suitable for processing 0.6-0.03MM and vein or placer ores, but it is unfavorable for sorting when the mud content is high. Now it has been widely used for processing iron ore, tungsten, tin ore, niobium tantalum ore, coastal and riverside ore sands, and gold mines. Spiral Chute Size Usage  Spiral Chute Size Usage

Spiral Chute Size Usage

The difference between energy-saving bal

The difference between energy-saving bal The drawbacks of difficult selection and

The drawbacks of difficult selection and Introduction to the characteristics of d

Introduction to the characteristics of d Types of mining magnetic separation equi

Types of mining magnetic separation equi What is the price of the Hesha magnetic

What is the price of the Hesha magnetic  The dry magnetic separator is applicable

The dry magnetic separator is applicable The price of dry magnetic separators is

The price of dry magnetic separators is  Selection range of fly ash magnetic sepa

Selection range of fly ash magnetic sepa Magnetic field intensity division of mag

Magnetic field intensity division of mag Different factors affecting the price of

Different factors affecting the price of How to achieve better magnetic separatio

How to achieve better magnetic separatio Industrial types and requirements of man

Industrial types and requirements of man Cement grinding process flow of ball mil

Cement grinding process flow of ball mil Optimization and Improvement of Wollasto

Optimization and Improvement of Wollasto Production process and main equipment of

Production process and main equipment of Complete set of beneficiation equipment

Complete set of beneficiation equipment  Complete equipment for quartz sand benef

Complete equipment for quartz sand benef Complete equipment for graphite ore bene

Complete equipment for graphite ore bene Complete set of beneficiation equipment

Complete set of beneficiation equipment  Complete set of mining beneficiation equ

Complete set of mining beneficiation equ Complete energy-saving beneficiation equ

Complete energy-saving beneficiation equ Complete set of manganese ore beneficiat

Complete set of manganese ore beneficiat Gold selection complete equipment

Gold selection complete equipment Complete beneficiation equipment

Complete beneficiation equipment Complete set of sand gold beneficiation

Complete set of sand gold beneficiation  Complete set of Baryte beneficiation equ

Complete set of Baryte beneficiation equ Complete beneficiation equipment for cop

Complete beneficiation equipment for cop Complete set of iron ore equipment

Complete set of iron ore equipment Complete machine for iron ore beneficiat

Complete machine for iron ore beneficiat Complete beneficiation production line

Complete beneficiation production line